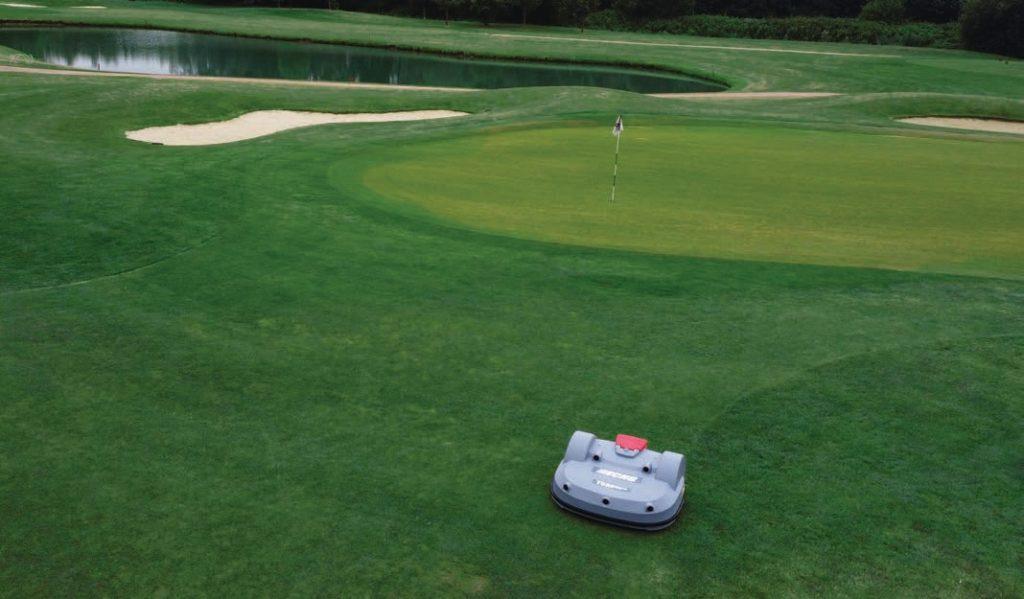

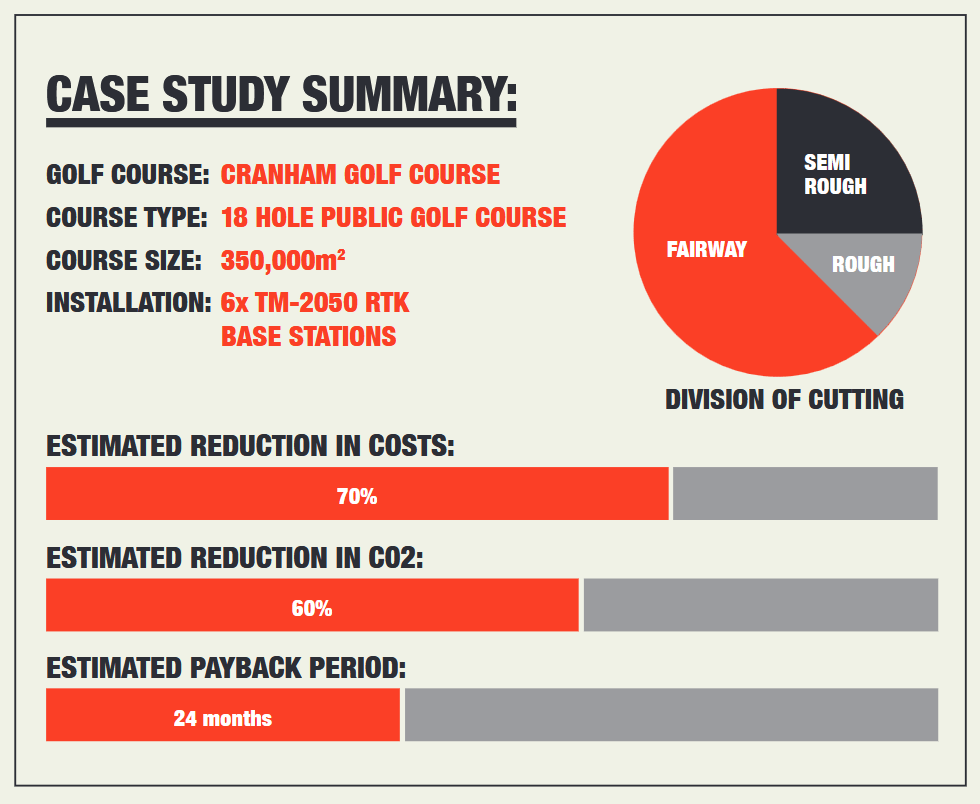

A par 67 spread out over 350,000m2 , Cranham prides itself on its island green, water features, and exceptionally maintained fairways.

“We’ve really built our reputation on the quality of the course,” says Barney Cameron, MD at Cranham. “We’re constantly investing into grounds maintenance – ultimately, the condition of the course is what’s going to keep players happy and keep them coming back over the long term.”

Despite its reputation, the current financial climate presents the same challenge for Cranham as it does for courses across the country. Rising costs for fuel, machinery servicing, and labour, are squeezing margins as Cranham tries to absorb increases and minimise the financial impact on players. Barney goes on to explain: “As a public course, there is no resting on our laurels.

We’re more vulnerable to rising costs than a member- only golf club who tends to have both fixed and diversified revenue streams. We quickly realised that we needed to find ways to minimise future cost increases without sacrificing our reputation for the quality of the course.”

Barney reached out to Sam Daybell at ECHO Robotics for help. “We had one eye on commercial robots for some time” explains Barney. “However, it wasn’t until we spoke to Sam at ECHO Robotics that we realised just how far the technology had come and ECHO seemed to have a proven track record with hundreds of golf installations across Europe.”

Sam, Head of Robotics for FGM Claymore (the U.K. distributor for ECHO Robotics), began by working with Barney to establish the specific objectives the club needed to achieve. It quickly became apparent that Cranham is lucky to have a team of highly skilled greenskeepers, but as Barney recounts, there are only so many hours in the day: “Our guys are excellent, a real asset to the business, but we realised that we were not able to utilise their expertise to the fullest. By the time they’d finished mowing the fairways and rough, there was limited time left for managing bunkers, repairing divots, green management, and improving drainage. It was like owning a sports car but mostly using it for the run to the supermarket rather than driving it at its fullest potential on a racetrack.”

Hiring additional labour certainly would not help Cranham in lowering operational costs – but no matter what, Barney realised that maintaining reputation as a well maintained, highly playable course was of paramount concern.

“We knew early on that we needed to offer a solution that would free-up the existing greenskeepers to do what they do best,” says Sam. “After an extensive site survey, I provided Barney with two TM-2050 fairway mowers to demonstrate what I had in mind.”

For two weeks, the ECHO robots mowed the fairways, 24 hours a day. “We just couldn’t believe the result,” says Barney. “We walked the course after only a couple of days and the finish was incredible. Given the huge area being cut, I was expecting to find at least a few areas missed or an uneven cut on slopes. I really thought we would need to tune the robot’s performance over a number of weeks – but it was near perfect from the start”. What was especially impressive was the way the robots dealt with the various obstacles of the course. Gateways, bunkers, trees and waterways are all detected and managed without human intervention. Everything is controlled from a user-friendly app which displays robot movements in real time.

Once the demonstration was concluded, Sam and Barney used the data gleaned through the trial to plan out a permanent installation. A further four TM-2050s were added (making six robots in total) and a mowing programme devised that included the rough and fairways for the whole course. Almost overnight, hundreds of hours of labour per week was released and the grounds team were reassigned to course improvement rather than fairway and rough mowing.

The benefits from the installation were immediately noticed – not just by the staff at Cranham, but also by the players. “The fairway grass quality is better than it was,” states Barney, “the overall presentation is improved through being cut a little-and-often and the team are reporting improved grass and sword densities throughout the course.”

However, this improvement wasn’t just anecdotal. Craig Brisley, Director of renowned agronomist ‘Collier Turf Care’, commented on his observations: “As a consultant and supplier of turf maintenance supplies to Barney, I have been watching, with great interest, the course development since Cranham installed ECHO Robotics.

“Last winter was one of the wettest on record. There were very few dry cut days, and Cranham was the only clay-based golf course I visited [in the Southeast of England] that was able to cut on its normal mowing schedule and which had consistent definition whilst also avoiding issues with worm cast smearing.

“Many clubs I visited during those winter months were only able to mow with their ride-on mowers or tractors during frosty days – which were few and far between. Even then, any mowing that was taking place was difficult, and the guys would have to work hard to minimise the mess caused from the machinery and worm casting. For sure, definition was lost, and come spring, they were all chasing a grass factory. What’s more, cutting wet areas with heavy machinery was causing mess and turf damage. For some customers, this was creating golf disruption for many months.

“There was a marked difference at Cranham. Not only were they cutting when others couldn’t during the winter, but I’ve also seen very distinctive differences in the spring, summer and autumn months. Grass loves being cut and the ‘round-the-clock’ mowing by the robot encourages density development. The condition of the fairways at Cranham has improved month-on-month to the point that, during my most recent visit, I concluded that they are the best fairways I have seen anywhere in the last 12 months!

“The grass is in amazing condition. There is great density and consistent definition with the other mown areas. In addition, the fairways have a high percentage of Ryegrass; which is a hard grass to cut cleanly in the wrong conditions, i.e. in the wet. At Cranham, the health of the rye was outstanding – cleanly cut and perfectly blended.”

This seal of approval from their turf consultant, reinforced the initial findings of Cranham’s groundskeepers and players. However, as Barney recalls, switching to ECHO Robotics created some other advantages for Cranham:

“What really took me by surprise was the secondary benefit that the robots have given us. This year, for the first time in a long time, we have had the capacity to really focus on drainage, bunker maintenance, and proper management of our hedgerows. Customers have noticed the difference and commented on the improvement. We used to have to sub-contract out this kind of work, but now we have the time to do it ourselves and, quite frankly, we do a better job of it. I feel that our greenskeepers are even more engaged these days too.

They’ve finally got the time to focus on what they’re best at and I can’t help but feel that they’re going home a little more satisfied with their work than they were before.” Of course, the primary benefit of installing ECHO Robotics is the financial saving it brings. Barney has calculated that his ‘real-world’ mowing costs are around 70% lower than when Cranham was using traditional fairway mowers. This is in line with Sam’s original estimation calculated after his initial site visit. Barney concluded by saying “I’ve been in the golf industry a long time and a win-win is a pretty rare occurrence in my experience. But installing ECHO has been the best investment I’ve made in those 25 years. It’s not just that we’re saving a lot of money this year, but those savings come year-after-year. I feel like we now have a bit more control over the business and we have the staff capacity to make course improvements that we’ve been wanting to do for years.”